Responder

Do you know anything about rigid-flex PCB?

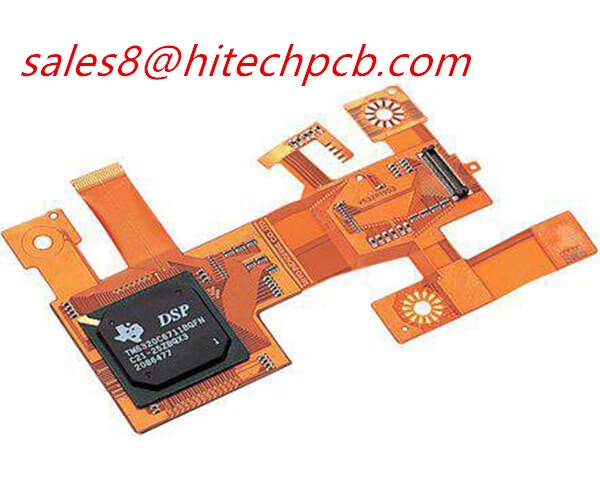

Rigid-Flex PCB (Printed Circuit Board) is a sophisticated type of circuit board that combines both rigid and flexible substrate materials within a single board. This design allows for complex, compact, and lightweight electronic assemblies, especially in applications requiring multiple geometric configurations or tight space constraints.

What is Rigid-Flex PCB?

Rigid sections: These are traditional, inflexible PCB parts made from rigid substrates like FR-4 or other materials that provide structural support.

Flexible sections: These parts are made from flexible materials such as polyimide or polyester films, allowing the PCB to bend, fold, or conform to different shapes.

The rigid and flexible sections are interconnected with flexible circuits, creating a single, integrated multi-layer PCB.

Key Features

Combination of Flexibility and Rigidity:

Enables the board to bend or fold without damage, while still providing solid support where needed.

Design Versatility:

Can accommodate complex geometries, multi-dimensional assemblies, or devices with moving parts.

Space and Weight Savings:

Reduces the need for connectors, cables, or multiple boards, leading to compact and lightweight designs.

Durability:

Designed to withstand mechanical stresses, vibrations, and flexing in the final application.

Advantages of Rigid-Flex PCBs

Design Flexibility: Ideal for intricate or unconventional shapes.

Reduced Size: Eliminates bulky connectors and cables.

Enhanced Reliability: Fewer connections decrease potential points of failure.

Simplified Assembly: Fewer parts lead to faster assembly and better reliability.

Cost-Effective for Complex Devices: Especially in aerospace, medical devices, mobile phones, wearables, and military applications.

Common Applications

Medical devices (e.g., imaging equipment)

Aerospace and military electronics

Mobile phones and tablets

Wearable devices

Automotive systems

Robotics and industrial machinery

Quomon.es

Quomon.es